Unified Hub for Smart Plants

Claims

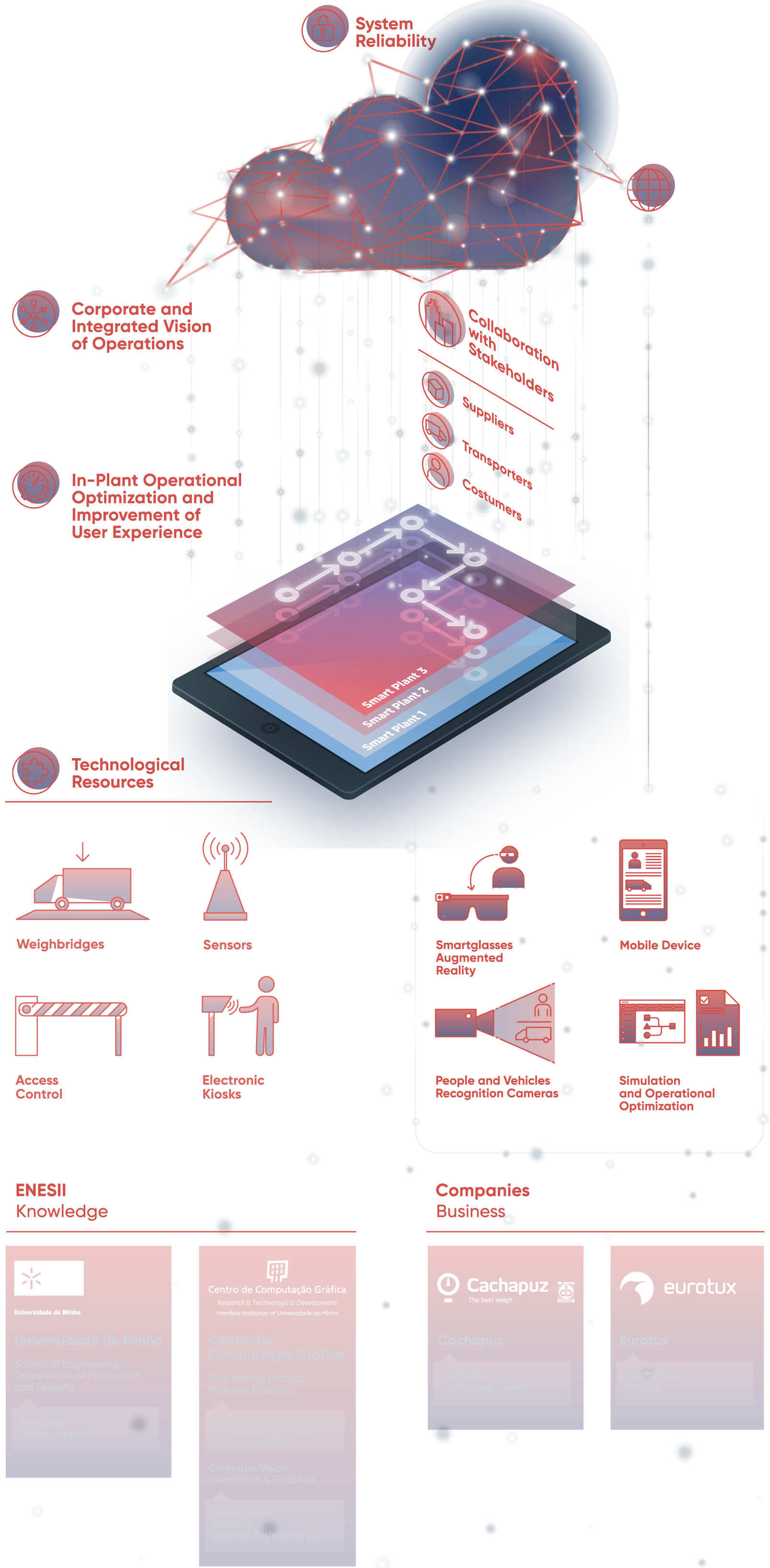

UH4SP’s objective is the development of a software architecture oriented to services and technological solutions, incorporating the paradigm of IoT and Industry 4.0, which promote the corporate and aggregated vision of operations of industrial units dispersed by several geographies through remote and local accesses; the construction of collaborative and cross-cutting tools; operations’ optimization and the usage experience in the industrial units and, finally, the reliability of the system.

The goal is to create a new offer, disrupting existing solutions in the market, recognized as innovative, differentiating and cutting edge in addressing the issues, needs and trends of processes and logistics flows in the industries of the future. It is not exhausted in a new technological architecture, but in a paradigm shift, in a more comprehensive vision of the business, leveraging its differentiation and operational efficiency.

Benefits

Promotes operational efficiency

Optimizes resource management

Strengthes relationships with clients, suppliers and transporters

Extends and reinforces the scope of action of the various entities involved in the value chain

Improves client service

Why UH4SP?

Ensuring the correct product at the right time, in the exact quantity, delivered at the right destination, by the authorized person, in perfect conditions and at the best price is the current challenge of the industrial units. It is, thus, necessary to design a logistic optimization and management system based on emerging concepts, technologies, tools and methodologies in the context of Internet-based industrial systems.

Visibility, safety and control in loading and unloading operations and in the movement of products, vehicles and people, automation of processes and collaboration with the various agents along the value chain, are fundamental vectors in the optimization of industrial companies’ logistics. The main goal is to create a Smart Plant = Efficiency, Effectiveness, Intelligence in the industrial unit.

Technical and scientific

objectives

Definition of mechanisms to design logical architectures for technology optimization platforms within the Industry 4.0 framework, aiming at the allocation of resources and robust and reliable data to entities within the value chain.

Design of services and business applications addressed to the various stakeholders invoking resources transparently and enabling the unit to benefit from tools that allow it to integrate services that provide information on and coming from the existing physical resources in the industrial units.

Development of new sounding algorithms and methods to improve the recognition of people and vehicles, interactions with drivers and remote technical assistance; it is intended to: 1/ make the access control less intrusive, more effective and efficient for vehicles and drivers; 2/ replace the hardware equipment by smart sensors and mobile devices; 3/ create optimized and intuitive orientation of the drivers in the route to be carried out in the industrial units; 4/ create remote assistance tools that allow a collaborative environment in telepresence using augmented reality.

Development of simulation and heuristic models aimed at logistic optimization; in this particular case they will be used as a means of visualizing and validating the optimization of the routes within the facilities, as well as to optimize the scheduling of the arrival of clients and suppliers to the facilities, allowing operational gains.

Development of computational platform (s) to support the operations of the system, using cloud management software: the goal is to reuse this platform in other industrial projects with similar requirements.

Development of a data storage platform in line with the Industry 4.0 requirements.

Technological foundations

and methodologies

The achievement of the main objective will be based on emerging concepts, technologies, tools and methodologies in the context of Internet-based industrial systems.

Industrial Internet of Things (IIoT) and Industry 4.0 technologies;

Large-scale architectures approaches using the Four-Step-Rule-Set (4SRS);

Service-oriented approaches (SOA architectures): business applications are divided into individual functions and modeled based on a service ecosystem that covers the entire industrial unit;

Adoption of cloud computing models;

Adoption of simulation and optimization mechanisms;

Adoption of innovative models and technologies in facial recognition, vehicle categorization, location, navigation assistance, telepresence, augmented reality;

Reliability assurance for disaster recovery and business continuity;

Expected

progress:

Multidimensional vehicle recognition: computer vision and graphic vision through the development of proprietary algorithms that analyze the number of axes and characterize the typology of the vehicle;

Driver identification: facial recognition based on the development of a system built on the forefront of computer vision / image processing;

Interaction with the driver through the use of mobile devices for operational front-office: replacement of service kiosks;

Drivers’ guidance on the industrial unit route: emerging navigation technologies;

Remote assistance in a telepresence collaborative view: augmented reality;

News

On September, the 25th, Nuno Santos, a researcher at CCG participated in the 9th IEEE TEMS International Conference on Intelligent Systems (IS'18) held from 25th til the 27th September in Funchal, Portugal, an important scientific communication event on research projects in the intelligent systems area.

Eurotux - co-promoter of the UH4SP project - organizes the Eurotux Ecosystem 2018 event today, starting at 2:00 p.m., at the Casa do Ribeirinho in Matosinhos. This year's edition takes place under the motto "Protect your Data, Protect your Business", in when the entry of the RGPD (General Regulation on Data Protection) is in place.

The National Exhibition Center in Santarém hosted the 55th National Agriculture Fair / 65th Ribatejo Fair from June 2nd to 10th, 2018, the highlight of which in 2018 was "The Olive tree".

Cachapuz, a leading company from Braga in providing state-of-the-art integrated systems (equipment, automation and software, and services) that optimize logistical processes for industrial weighing, presented its latest innovation benchmark, on May, the 24th at the Chachapuz’s Open Day venue.

In the week of May 21-25th in Porto, the scientific dissemination of the UH4SP project was reinforced with the presence of Nuno Santos of CCG at the 6th International Workshop on Large-Scale Agile Development (LargeScaleAgile'18), a member of the 19th International Conference on Agile Software Development ( XP'18) (https://www.agilealliance.org/xp2018/). In this conference, Nuno Santos presented the work "An experience report on using architectural models within distributed Scrum teams contexts". (Santos, N., Pereira, J., Morais, F., Barros, J., Ferreira, N. & Machado, R.J., 2018).

Cachapuz, a leading company from Braga in providing state-of-the-art integrated systems (equipment, automation and software, and services) that optimize logistical processes for industrial weighing, has seized this opportunity to present its latest innovation benchmark, the UH4SP - United Hub For Smart Plants – which couples almost a century of groundbreaking pioneering history – at the Agro Exhibition in Braga.

Cachapuz, a leading company from Braga in providing state-of-the-art integrated systems (equipment, automation and software, and services) that optimize logistical processes for industrial weighing, presented its latest innovation benchmark, the UH4SP - United Hub For Smart Plants in Beja at the Ovibeja fair.

On March 22nd, the first interim audit of the UH4SP project (United Hub for Smart Plants) took place at Cachapuz's facilities in accordance with the Portugal2020 application process. In this audit, all the elements representing the UH4SP Consortium were prsent - Cachapuz, Department of Production and Systems of the University of Minho, CCG / ZGDV Association - Computer Graphics Center and Eurotux – who, during 4 hours, had the opportunity to present the project developments to the designated auditor for this project.

Cachapuz, a Portuguese company from Braga, leader in the industrial weighing sector, presents another milestone that adds to almost a century of history already filled with pioneering developments and implementations of state-of-the-art technological solutions.

Intermediate results from the UH4SP project are already being disseminated scientifically!

A chapter entitled "Specifying Software Services for Fog Computing Architectures Using Recursive Model Transformations" was accepted in the book that is being developed "Fog Computing: Concepts, Frameworks and Technologies", published by Springer (forecasted for the third quarter of 2018).

On February, the 22nd, 2017, the UH4SP working group visited Cimpor’s Souselas Production Center – a Cachapuz’s strategic partner. The main goal of this visit was to show them the on-going operations of a factory with automated vehicles flows.

The elements of the UH4SP consortium (United Hub for Smart Plants) met on October, the 10th, 2016 for the first time. It was na informal meeting where the representatives of Cachapuz, the Department of Production and Systems of the University of Minho, the Association C.C.G / ZGDV - Computer Graphics Center and Eurotux, came together to begin a journey fulfilled with disruptive challenges.

Consortium

Cachapuz belongs to one of the largest worldwide industrial weighing groups based in Italy. It is leader and pioneer in Portugal in the design and manufacturing of weighing equipment and an European reference in the design and implementation of software solutions for industrial weighing logistics. Its name exists since 1694 but it is only since 1920 that Cachapuz manufactures scales, always weighing with innovation.

As its current strategic priority Cachapuz aims at the adequate introduction of innovation in its products and services in order to ensure and reinforce its weighing solutions in national and international markets with a vision of future growth and evolution. Much of Cachapuz's current activity is focused on the development of innovative solutions for the automation of processes in the industrial sector.

Department of Production and Systems (DPS) of the School of Engineering of the University of Minho

The area of Production and Systems was created in 1976, within the scope of the definition of the organic structure of the University of Minho. In 1989, the designation of this area became Department of Production and Systems (DPS) of the School of Engineering of the University of Minho. The Production and Systems Department was a pioneer in teaching Industrial Engineering and Management in Portugal, at the time with the designation of Production Engineering, in courses whose main objective was to train Engineers to deal with the problems of optimization and rationalization of the resources of the industry in small and medium-sized enterprises.

The Bachelor's degree in Production Engineering was created in 1978; at present, the DPS’ mission is to generate, disseminate and apply scientific and technological knowledge in the fields of Systems Engineering and Industrial Processes and Industrial Management and Technology, and thus contribute to the accomplishment of the mission of the School and that of University of Minho.

Associação C.C.G/ZGDV - Centro de Computação Gráfica

Instituição de interface

Universidade

CCG is na entity qualified by the National Scientific and Technological System (SCTN) for the Provision of Services of Research and Technological Development and for Consulting and Supporting Services to the Innovation of companies; it is also a founding member of the network GraphicsMedia.net - International Network for Cooperation in Applied Research in Computer Graphics, Multimodal Technologies-Multimedia and Interactive Visual Digital Technologies. CCG will involve elements from two departments in this project:

CVIG (Computer Vision Interaction and Graphics): it is a domain related to computer vision and computer graphics, which has three key pillars: (i) computer vision, (ii) computer graphics, (iii) human-machine interaction, highlighting three technological modules: (i) virtual reality, (ii) augmented reality and (iii) virtual actors. The importance of the involvement of this department is related to its computer vision and augmented reality skills.

EPMQ (Engineering Process Maturity and Quality): is the field of applied research, in the scope of quality and maturity of the process of engineering systems and information technologies. The intervention of this department in the project relates to the skills of defining business models and cloud computing architectures development.

Specialized in planning, integration and implementation of computer systems, Eurotux offers Information Technology solutions customized to its clients’ needs. Created in 2000, as an initiative promoted by a group of teachers from University of Minho, Eurotux's staff is made up of resources mostly with a bachelor's or a master's degree in computer science.

The applied technologies range from open source, inherently transparent, reliable and high performance products – their focus from foundation - to the proprietary products of Microsoft, VMWare, EMC, Cisco, Oracle, IBM, among others. Projects involving Eurotux focus on safety criteria, contingency planning and high system availability. The company specializes in consolidation and security, has a privileged position in the Open Source area and increasingly intervenes in environments where the interoperability of different solutions is a determining factor.

The largest component of Eurotux's turnover is the provision of services, particularly the deployment and remote administration of systems and networks, as well as 24x7 monitoring and support.